Bag filter is a kind of multi-purpose filtration equipment with novel structure, small size, simple and flexible operation, energy saving, high efficiency, closed work and strong applicability. mainly composed of filter cylinder, filter cylinder cover and quick opening mechanism, stainless steel filter bag reinforcing screen and other main components.

Product Description

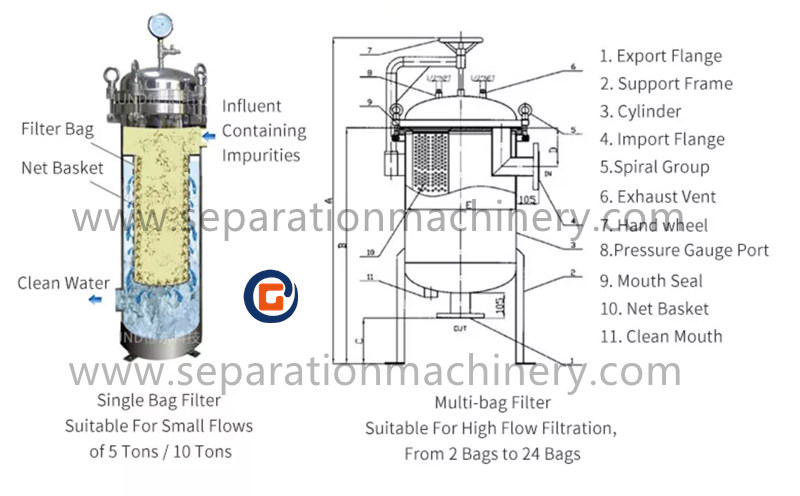

Bag filter is a kind of multi-purpose filtration equipment with novel structure, small size, simple and flexible operation, energy saving, high efficiency, closed work and strong applicability. Bag filter is a kind of pressure filter device, mainly composed of filter cylinder, filter cylinder cover and quick opening mechanism, stainless steel filter bag reinforcing screen and other main components, filtrate by the side inlet pipe of the filter shell into the filter bag, the filter bag itself is installed in the reinforced net basket, liquid penetrates through the required fineness level of the filter bag to obtain qualified filtrate, impurity particles are intercepted by the filter bag.

Filter structure

The structure, principle, features and applications of multi-bag filter is same as single bag filter. Regarding the inlet/outlet type, normally it adopts " side-in/bottom-out" or " side-in and side-out" type (especially we also can supply " bottom-in and bottom-out" type). Regarding the opening type, it has: eyebolts, rocker and quick open. The bag quantity can be 1-24 bags. The material can be carbon steel, SU304, SUS316L and PP. According to the nature and temperature of the material filtered, the O-Ring's material can be customized to meet your needs. Application: Chemical industry, pharmacy, automobile industry, light industry, food industry, electroplating industry, etc.

Application

1. Food and beverage industry: beer, wine, wine, sake, liquor, wine, fruit juice, bottled water, tea drinks, soy milk, syrup, dairy products, food additives, water filtration to clarify the process and CIP.

2. Petrochemical industry: all kinds of lubricants and oil, glue, chemical fiber manufacturing process of various solution was filtered.

3. Oil and gas industry: amine desulfurization, dehydration flux filter, oil field water, completion fluid filtration.

4. Car paint, painting industry: paint, electrophoretic paint, pre-treatment fluid, paint and paint raw materials and solvent filtration

5. Textile, printing and dyeing, paper making industry: spinning liquid, dyes, flux, water, additives, adhesives filter.

6. Edible oils and soap industry: polishing purification of edible oil, soap raw materials and water filtration.

7. Pharmaceutical industry: a variety of pharmaceutical intermediates, pharmaceutical raw materials, solvent filtration.

8. The electronic and electroplating industry: a variety of plating solution and water filtration.

9. Machining industry: a variety of cutting fluid, coolant and cleaning liquid filtration.

Technical Parameter

| Model | Bag quantity | Filter area(m²) | Inlet/Outlet diameter (mm) | Max. reference flow (m3/h) | Working pressure (Mpa) |

| DL2-1 | 1 | 0.5 | 50 | 30 | 0.5 |

| DL2-2 | 2 | 1 | 50 | 60 | 0.5 |

| DL2-3 | 3 | 1.5 | 50 | 90 | 0.5 |

| DL2-4 | 4 | 2 | 100 | 120 | 0.5 |

| DL2-5 | 5 | 2.5 | 150 | 150 | 0.5 |

| DL2-6 | 6 | 3 | 200 | 180 | 0.5 |

| DL2-7 | 7 | 3.5 | 200 | 210 | 0.5 |

| DL2-8 | 8 | 4 | 250 | 240 | 0.5 |

| DL2-10 | 10 | 5 | 250 | 300 | 0.5 |

| DL2-12 | 12 | 6 | 300 | 360 | 0.5 |

| DL2-14 | 14 | 7 | 300 | 420 | 0.5 |

| DL2-16 | 16 | 8 | 300 | 480 | 0.5 |

| DL2-18 | 18 | 9 | 350 | 540 | 0.5 |

| DL2-20 | 20 | 10 | 350 | 600 | 0.5 |

| DL2-22 | 22 | 11 | 350 | 660 | 0.5 |

| DL2-24 | 24 | 12 | 350 | 720 | 0.5 |