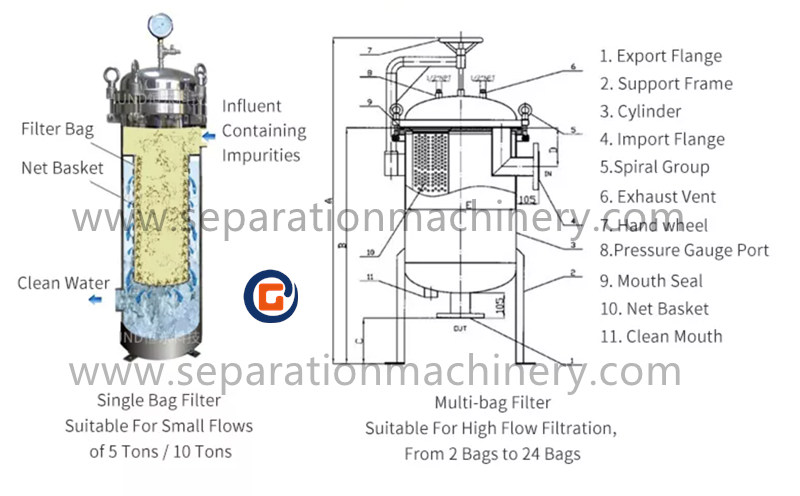

Bag filter is a kind of pressure filter device, are divided into: single bag filters, multi-bag filters and sandwich filters. Multi-bag filter for high flow filtration. The material can be carbon steel, SU304, SUS316L and PP. Application: Chemical industry, pharmacy, automobile industry, light industry, food industry, electroplating industry, etc.

Product Description

Bag filter is a kind of pressure filter device, are divided into: single bag filters, multi-bag filters and sandwich filters. Multi-bag filter for high flow filtration. The material can be carbon steel, SU304, SUS316L and PP. Application: Chemical industry, pharmacy, automobile industry, light industry, food industry, electroplating industry, etc.

Filter structure

The structure, principle, features and applications of multi-bag filter is same as single bag filter. Regarding the inlet/outlet type, normally it adopts " side-in/bottom-out" or " side-in and side-out" type (especially we also can supply " bottom-in and bottom-out" type). Regarding the opening type, it has: eyebolts, rocker and quick open. The bag quantity can be 1-24 bags. The material can be carbon steel, SU304, SUS316L and PP. According to the nature and temperature of the material filtered, the O-Ring's material can be customized to meet your needs. Application: Chemical industry, pharmacy, automobile industry, light industry, food industry, electroplating industry, etc.

Application

1. Food and beverage industry: beer, wine, wine, sake, liquor, wine, fruit juice, bottled water, tea drinks, soy milk, syrup, dairy products, food additives, water filtration to clarify the process and CIP.

2. Petrochemical industry: all kinds of lubricants and oil, glue, chemical fiber manufacturing process of various solution was filtered.

3. Oil and gas industry: amine desulfurization, dehydration flux filter, oil field water, completion fluid filtration.

4. Car paint, painting industry: paint, electrophoretic paint, pre-treatment fluid, paint and paint raw materials and solvent filtration

5. Textile, printing and dyeing, paper making industry: spinning liquid, dyes, flux, water, additives, adhesives filter.

6. Edible oils and soap industry: polishing purification of edible oil, soap raw materials and water filtration.

7. Pharmaceutical industry: a variety of pharmaceutical intermediates, pharmaceutical raw materials, solvent filtration.

8. The electronic and electroplating industry: a variety of plating solution and water filtration.

9. Machining industry: a variety of cutting fluid, coolant and cleaning liquid filtration.

Technical Parameter

| Model | Bag quantity | Filter area(m²) | Inlet/Outlet diameter (mm) | Max. reference flow (m3/h) | Working pressure (Mpa) |

| DL2-1 | 1 | 0.5 | 50 | 30 | 0.5 |

| DL2-2 | 2 | 1 | 50 | 60 | 0.5 |

| DL2-3 | 3 | 1.5 | 50 | 90 | 0.5 |

| DL2-4 | 4 | 2 | 100 | 120 | 0.5 |

| DL2-5 | 5 | 2.5 | 150 | 150 | 0.5 |

| DL2-6 | 6 | 3 | 200 | 180 | 0.5 |

| DL2-7 | 7 | 3.5 | 200 | 210 | 0.5 |

| DL2-8 | 8 | 4 | 250 | 240 | 0.5 |

| DL2-10 | 10 | 5 | 250 | 300 | 0.5 |

| DL2-12 | 12 | 6 | 300 | 360 | 0.5 |

| DL2-14 | 14 | 7 | 300 | 420 | 0.5 |

| DL2-16 | 16 | 8 | 300 | 480 | 0.5 |

| DL2-18 | 18 | 9 | 350 | 540 | 0.5 |

| DL2-20 | 20 | 10 | 350 | 600 | 0.5 |

| DL2-22 | 22 | 11 | 350 | 660 | 0.5 |

| DL2-24 | 24 | 12 | 350 | 720 | 0.5 |