Z-type bucket elevator has obvious advantages such as large conveying capacity, high lifting height, stable and reliable operation, and long life. This elevator is suitable for conveying powdery, granular and small blocks of non-abrasive and small abrasive materials.

Description

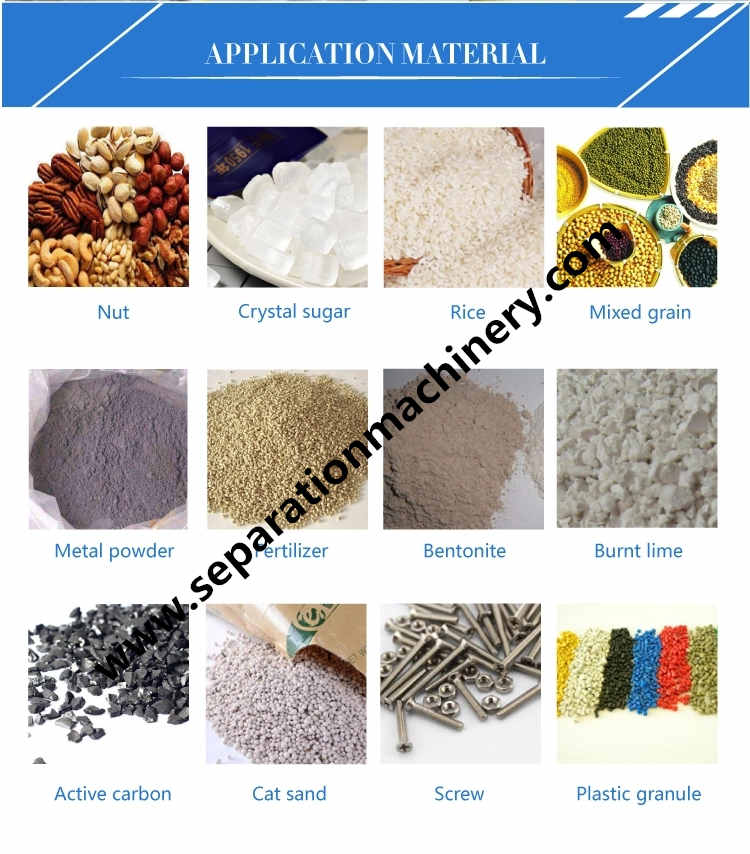

Z-type bucket elevator has obvious advantages such as large conveying capacity, high lifting height, stable and reliable operation, and long life. This elevator is suitable for conveying powdery, granular and small blocks of non-abrasive and small abrasive materials. It is currently used for feeding of weighing packaging machines, feeding of color sorters and re-feeding, automation The three-dimensional circulation of the production line loads and unloads. Our products are currently operating normally in the following automated production industries: health food industry, puffed food industry, feed industry, confectionery industry, dried and fresh fruit industry, PVC plastic pellets, pet food industry, grain processing industry, chemical and pharmaceutical industry, Hardware and electrical materials industry, military industry manufacturing, etc.

Features

1)Economy

2)Green

3)Energy conservation

4)Operation

Advantage

1.Conveying speed are adjustable, Can realize uniform feeding .

2.Zero crushing in conveying process .

3.Full-closed structure, no pollution .

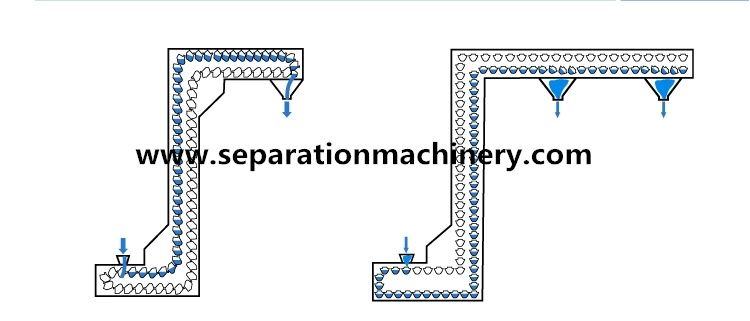

4.Single discharge but also for muti-discharge .

5.The bucket is made of food grade ABS material, which can resistance to the high and low temperature.

Application

Bucket Elevators are very well suited for a broad range of free flowing products in the food, agriculture, pharmaceutical, cosmetic, chemical industry, .such as snack foods, frozen foods, vegetables, fruits, confectionary. Chemicals and other granules.

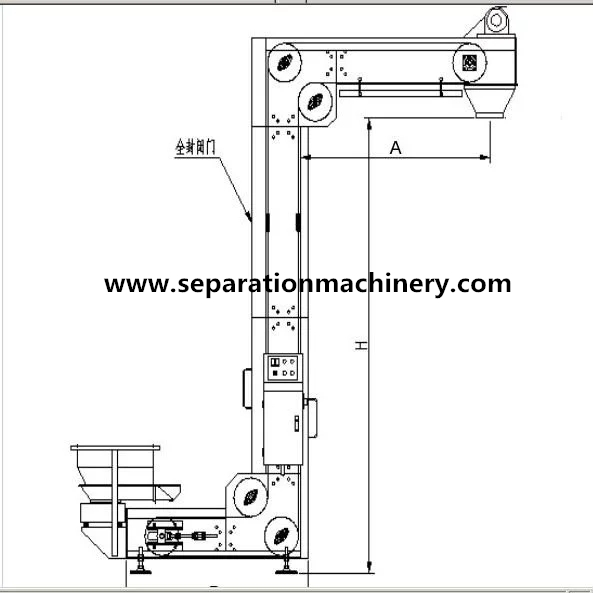

Working Principle

The incoming product is fed to the bucket elevator continuously and very gently by means of a vibratory feeder.The edges of the buckets overlap each other in the inlet section and therefore prevent spillage of kernels. Due to the pivoted mounting of buckets in the chain, buckets keep their horizontal position all through the way around in the conveyor until they finally reach the outlet. There, each bucket is tilted and the product falling out is gently led into the outlet hopper.

Technical Parameter

| Model | ZT-2L | ZT-5L | ZT-7L | ZT-10L |

| Capacity(m3/h) | 0-6 | 0-12 | 0-15 | 0-20 |

| Running Speed(m/min) | 10-12 | 10-12 | 10-12 | 10-12 |

| Lifting Height | Up To 50m | Up To 50m | Up To 50m | Up To 50m |

| Bucket Volume(L) | 2L | 5L | 7L | 10L |

| Power(KW) | 0.75-22 | 0.75-22 | 0.75-22 | 0.75-22 |

| Outlets | 1—15 pcs | 1—15 pcs | 1—15 pcs | 1—15 pcs |