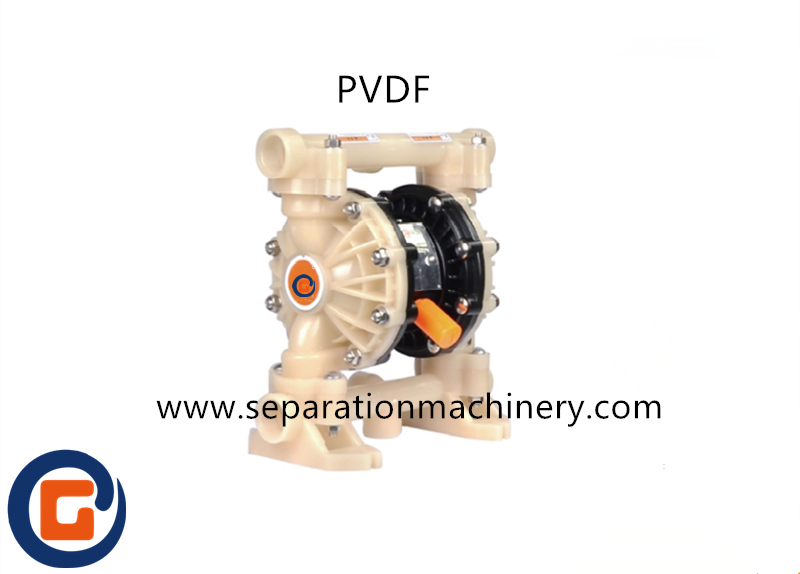

The perfluorinated material (PVDF) pneumatic double diaphragm pump has the characteristics of strong toughness, aging resistance and strong corrosion resistance. It is suitable for chemical electronics, petrochemicals, conveying solvents, electroplating solutions, cleaning solutions, nitric acid, waste acids and corrosive acids and other media transportation.

Introduction

The perfluorinated material (PVDF) pneumatic double diaphragm pump has the characteristics of strong toughness, aging resistance and strong corrosion resistance. It is suitable for chemical electronics, petrochemicals, conveying solvents, electroplating solutions, cleaning solutions, nitric acid, waste acids and corrosive acids and other media transportation.

Application

The diaphragm pumps can be applied to ship/bus/train unloading, chemical production, batch treatment and mixing, large tank or tank area conveying, common feed-conveying, system flushing, wastewater treatment or fluid filtration, packaging or filling, recycling and recycling.

| Application Filed | Materials |

| Chemical | Acid, alkali, solvent, suspension, dispersion system. |

| petrochemical industry | thick oil, grease, slurry, sludge |

| Coating industry | Resin, solvent, colorant, paint |

| Daily chemical industry | Detergent, shampoo, emulsion, emulsion, hand cream, surfactant |

| Ceramic industry | Mud, porcelain pulp, lime pulp, clay pulp |

| Mining industry | Coal slurry, magma, mud, mortar, lubricating oil |

| Water treatment | Lime slurry, soft sediment, waste water, chemicals, wastewater |

| Food industry | Liquid semi-solid, chocolate, salt water, vinegar, syrup, vegetable oil, soybean oil, honey |

| Beverage industry | Yeast, syrup, concentrate, gas - liquid mixture, wine, juice, corn slurry |

| Medical | Solvent, acid, alkali, plant extract liquid, ointment and other kinds of pharmaceutical liquid |

| Paper making | Adhesives, resins, paints, inks, pigments, hydrogen peroxide |

| Electronics | Solvent, plating solution, cleaning solution, nitric acid, waste acid, corrosive acid, polishing solution |

| textile | Dye stuff, resins, gels |

| Building | Cement paste, ceramic tile binder, rock paste, ceiling finish |

| Car industry | Polishing emulsion, oil, coolant, automotive primer, oil emulsion, varnish, varnish additive, degreaser |

| furniture | Adhesives, varnishes, dispersants, solvents, colorants, wood gums, epoxy resins, starch binders |

| Metallurgy, casting and dye | Metal pulp, hydroxide and carbonized pulp, dust washing pulp |

Technical Parameter

| Model | Max. Flow rate(L/min) | Max. lift head(m) | Max. Suction Height(m) | Outlet Pressure(Mpa) | Caliber(DN) | Air inlet size(inch) | Max. Permitted particles(mm) | Air consumption(scfm) |

| QBY4-10 | 22 | 70 | 4 | 7 | 10 | 1/4 | 1.5 | 6.3 |

| QBY4-15 | 22 | 70 | 4 | 7 | 15 | 1/4 | 1.5 | 6.3 |

| QBY3-20 | 57 | 70 | 4.5 | 7 | 20 | 1/4 | 2.5 | 12.7 |

| QBY3-25 | 57 | 70 | 4.5 | 7 | 25 | 1/4 | 2.5 | 12.7 |

| QBY3-32 | 151 | 84 | 5.48 | 8.4 | 32 | 1/2 | 3.2 | 23.66 |

| QBY3-40 | 151 | 84 | 5.48 | 8.4 | 40 | 1/2 | 3.2 | 23.66 |

| QBY3-50 | 378.5 | 84 | 5.48 | 8.4 | 50 | 1/2 | 4.8 | 32 |

| QBY3-65 | 378.5 | 84 | 5.48 | 8.4 | 65 | 1/2 | 4.8 | 32 |

| QBY3-80 | 568 | 84 | 5.48 | 8.4 | 80 | 1/2 | 6.4 | 45 |

| QBY3-100 | 568 | 84 | 5.48 | 8.4 | 100 | 1/2 | 6.4 | 45 |

| QBY3-125 | 1041 | 84 | 7.6 | 8.4 | 125 | 3/4 | 10 | 82.6 |

Related Pump Products