Our company produces various types of chamber and plate frame mechanical filter presses, hyd raulic filter presses, diaphragm filter presses, automatic filter presses, quick-opening filter pr esses, and filter press accessories, with reliable quality and complete specifications.

Product description:

Our company produces various types of box and plate frame mechanical filter presses, hyd raulic filter presses, diaphragm filter presses, automatic filter presses, quick-opening filter pr esses, and filter press accessories, with reliable quality and complete specifications.

1. Specifications : Types of 200, 380, 500, 700, 870, 1000, 1250, 1500, 2000, and various special-shaped filter plates and filter presses.

2.The filtering area is up to 2000m

3. Filter plate material: stainless steel, cast iron, rubber, reinforced polypropylene, glass fiber with high temperature resistance, pp-30 elastomer membrane plate.

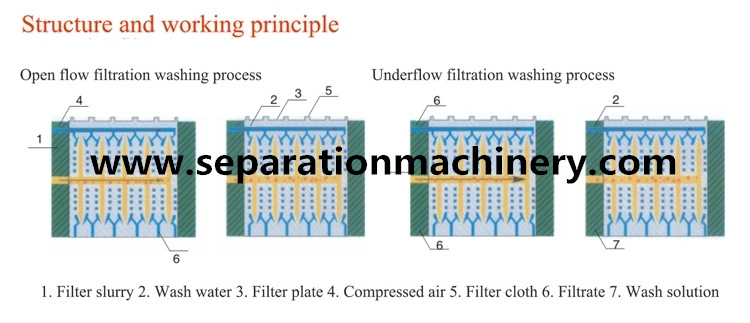

4. Liquid flow forms are open flow, dark flow, washable, non-washable, medium feed, corner feed, upper and middle feed and other forms.

5. Filter plate compąction methods are: manual sçrew compaction, electro-mechanical com paction fluid, and hydraulic cylinder compaction. For special requirements of the filter press can be resolved separately.

6. The whole maçhine doęs not include material infusion pumps and filter cloths. If nece ssary supplies can be specified in the contract.

7. According to the special requirements of customers, our company can produce non standard models and products suitable for your needs.

8. If technical data changes due to model improvements, the actual size at the time of ordering shall prevail.

Working principle:

Application scope of automatic filter press:

Filter Press Machine are widely applied in various kinds of solid-liquid procession, such as petroleum, chemical, metallurgy, environmental protection, food, beverage, pharmaceutical, sugar, starch, paper, coal washing, ceramics, mineral processing, and many other industries.

Automatic Filter Press Technical Data:

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XZ/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XZ/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XZ/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XZ/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 | ||||

| XZ/2000-30U | 500 | 2000*2000 | 40 | 7450 | 68 | 0.5-1.5 | 36500 | 10140*3030*2400 |

| 600 | 8960 | 82 | 40000 | 11275*3030*2400 | ||||

| 800 | 11990 | 110 | 48000 | 13540*3030*2400 | ||||

| 1000 | 14900 | 127 | 56000 | 14920*3030*2400 |