800 Round Plate filter press is always used for stone, kaolin, wastewater, ceramic, building materials industry, its special advantage is its high working pressure, and the maximum pressure can reach 2.5MPa, ensure drier filter cake.

Introduction of 800 Round Filter Press

800 Round Plate filter press is always used for stone, kaolin, wastewater, ceramic, building materials industry, its special advantage is its high working pressure, and the maximum pressure can reach 2.5MPa, ensure drier filter cake.

Features of 800 Round Plate Filter Press

1.Automatic hydraulic maintaining pressure.

2.Main beam is made of high quality carbon steel with sand blasting processing and it is of high intensity and corrosion resisting.

3.Pure reinforced PP filter plate resistes to stronger corrosion and endure high pressure and service longer.

4.Every plates is tested under high pressure 27 MPa.

5.The flatness of the filter plate is lower than 25μm.

6.Hydraulic pistons are made by steel 45 after surface processing with feature of high hardness, anti-wearing, long life-span.

Working Principle of 800 Round Plate Filter Press

Filter chambers of ceramic filter press formed between pressed filter plates when the pressing device drives the pressing plate.

Feeding pump squeezes material through the pore from thrust plate into the filter chambers, solid particles are intercept in the filter chambers forming cake, while liquid was discharged out of the machine through cake and filter cloth.

Application scope of 800 Round Plate Filter Press

It's mainly used for stone wastewater, ceramics, kaolin, construction material,marble, zeolite powder etc. The cake moisture is very low.

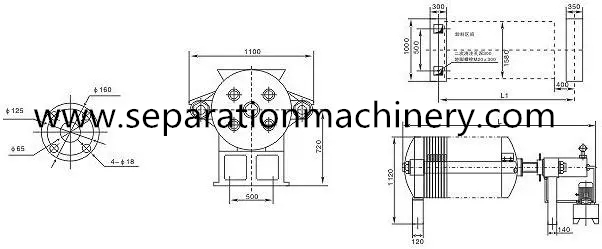

Technical Data

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XZ/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XZ/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XZ/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XZ/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 | ||||

| XZ/2000-30U | 500 | 2000*2000 | 40 | 7450 | 68 | 0.5-1.5 | 36500 | 10140*3030*2400 |

| 600 | 8960 | 82 | 40000 | 11275*3030*2400 | ||||

| 800 | 11990 | 110 | 48000 | 13540*3030*2400 | ||||

| 1000 | 14900 | 127 | 56000 | 14920*3030*2400 |