Filter press is an effective type of dewatering equipment working in batches, applicable to various solid-liquid separation. Filter press is effective, easy to use, suitable for large filtration plants that requires a high degree of automation or centralized control.

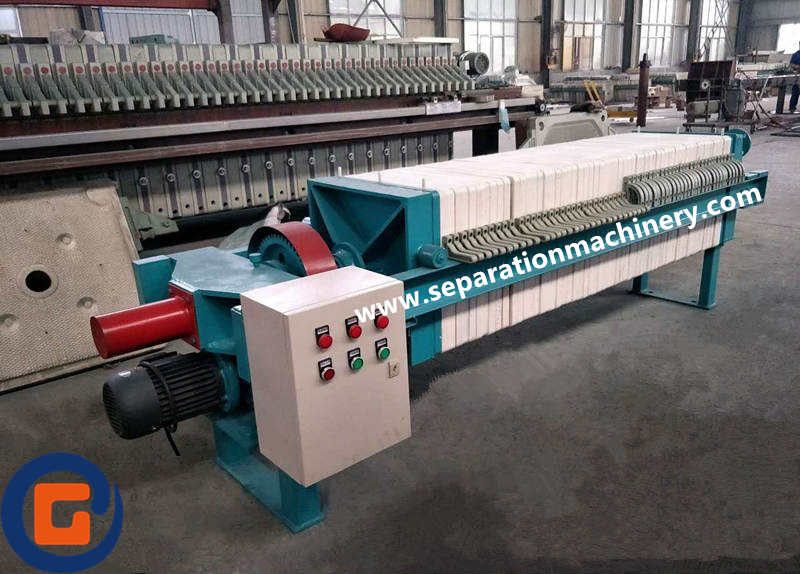

Introduction of Hydraulic Filter Press:

Filter press is an effective type of dewatering equipment working in batches, applicable to various solid-liquid separation. Filter press is effective, easy to use, suitable for large filtration plants that requires a high degree of automation or centralized control, with filter pressure of 0.8 Mpa min.. The whole machine is designed with integration of machine, electricity and liquid, can realize automatic pressing, filtering, draining, squeezing, loosening, drawing board, and so on, with a high degree of automation, large production capacity, low liquid content in filter cake, high unit output, requiring only very limited area for installation&operation. Widely used in petroleum, chemical industry, dye, metallurgy, pharmacy, food, paper making, coal washing,water treatment and sewage treatment and so on all kinds of solid-liquid separation is required.

Automatic filter press is on the basis of the pressure filter, according to user's different requirements for filter press equipment automation degree, choose to increase automatic plate system, auxiliary varicose arm of discharging slag system, single lever water flushing system, flap hydraulic system, PLC control system and other auxiliary facilities, in order to reduce the workers labor intensity, improve production efficiency.

Main Structure:

Frame: The steel frame acts as a clamping device for the filter plates.

Filter Plates: A filter cake forms in the chambers between filter plates.

Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Available options according to:

Closing mode: manual, gear drive, hydraulic;

filter plate structure: recessed plate, diaphragm squeeze (membrane) plate; plate &frame

filter plate material: PP, rubber, cast iron, stainless steel;

Filter Plate size(mm): 390, 500, 700, 800,870 ,1000, 1250, 1500,2000

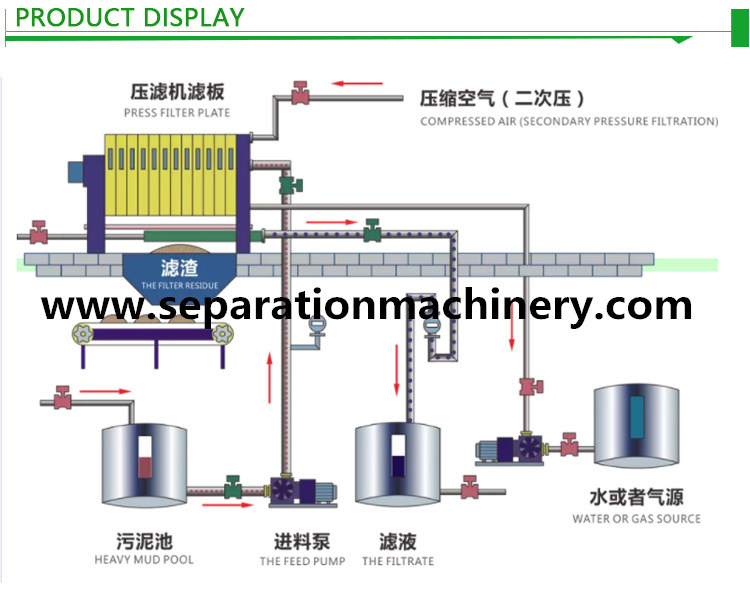

Working principle:

The mixture slurry is pumped through the mediating medium(filter cloth) ,the solid will stay in the filter chamber formed by two filter plates and gradually pile up on the filter cloth to form a filter cake. and the liquid part is permeable to filter cloth, then the clear liquid that contains no solid flow out of the filter press.The filtration chamber of the chamber filter press is composed of two adjacent filter plate. The mainly advantage of this type is less wear during feeding, fast filtration, high temperature and high pressure resistance, good seal performance, uniform filter cake washing , moisture content is low, and the filter chamber pressure are evenly not easy to damage filter plate, It is suitable for all solid-liquid separation industries.

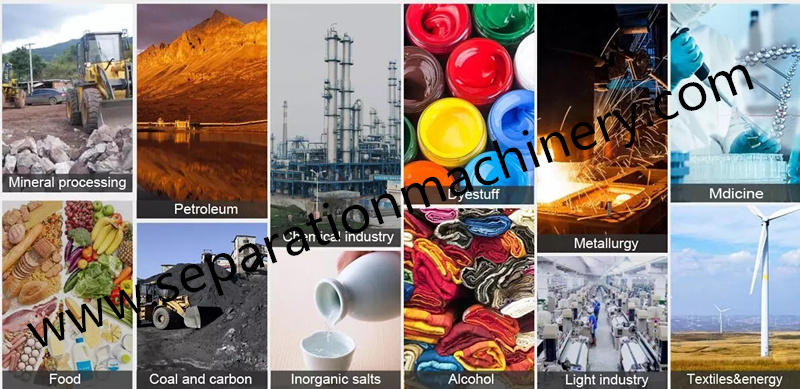

Applications:

Stone Fabrications

Mining & Energy

Chemical Processing

Industrial Wastewater

Municipal Wastewater

Power plants

Sand Washing Plants

Textile Plants

Oil Refining Plants

Gold/Copper Leaching Process

Biomass Sludge treatment

Lime Softening

Metal Finishing

Ready Mixed Concrete

Car & Truck Washes

Hydraulic Filter Press Technical Data:

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XY/520-25U | 4 | 520*520 | 25 | 40 | 9 | 0.5-1.5 | 560 | 1915*700*860 |

| 6 | 60 | 14 | 630 | 2145*700*860 | ||||

| 8 | 80 | 19 | 700 | 2375*700*860 | ||||

| 12 | 120 | 29 | 830 | 2835*700*860 | ||||

| 16 | 160 | 39 | 980 | 3295*700*860 | ||||

| 18 | 176 | 44 | 1160 | 3525*700*860 | ||||

| 20 | 200 | 49 | 1360 | 3755*700*860 | ||||

| XY/700-25U | 20 | 700*700 | 25 | 250 | 24 | 0.5-1.5 | 2210 | 3120*1100*1100 |

| 30 | 380 | 37 | 2660 | 3785*1100*1100 | ||||

| 40 | 500 | 49 | 3080 | 4395*1100*1100 | ||||

| XY/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XY/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XY/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XY/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 |