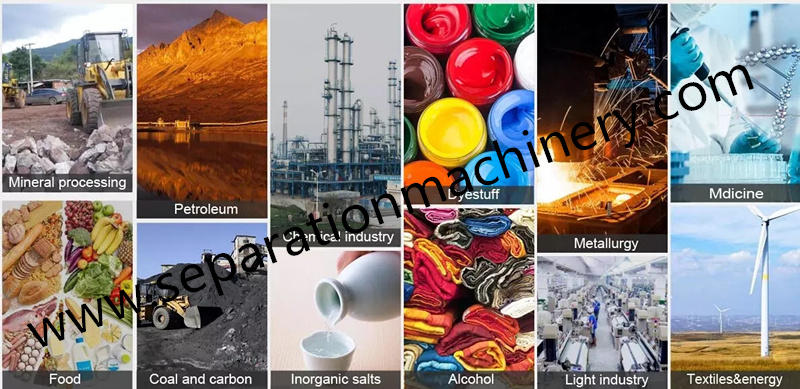

This High Pressure Automatic Filter Press For Quarry Mill And Ceramic Factory, with high automation, stable performance, safety and reliability. It is the first choice of customers in metallurgy, natural gas, papermaking, coking, pharmaceutical, food, brewing, fine chemicals, sewage treatment and other industries. It has been widely used in the field of solid-liquid separation.

Introduction of Automatic Filter Press:

This High Pressure Automatic Filter Press For Quarry Mill And Ceramic Factory, with high automation, stable performance, safety and reliability. It is the first choice of customers in metallurgy, natural gas, papermaking, coking, pharmaceutical, food, brewing, fine chemicals, sewage treatment and other industries. It has been widely used in the field of solid-liquid separation.

The process of one batch filtration is:

Pressing -- Feeding material - Filtering -- Discharging cake.

1.Closing of the filter plates: when start the press button on the PLC control cabinet, the moving head plates will be activated by the hydraulic clamping the plates.

2.Filling: The sludge (or slurry) will be pumped into the chamber one by one. When all chambers are full off filter cake, the filtration is finished.

3.Filter opening: The moving head is drawn back to disengage the first filtration chamber. The cake falls will drop from the plates under gravity.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000.

Filter Press Usages:

Ceramics class: kaolin, superfine glass powder, fire-proof material, silica sand, spray soil grain, mud, abrasive resistance and meters brick materials, artificial black lead, hydrated lime, mica, aluminum oxide, calcium carbonate.

Technical Data:

| Model | Filter area (m2) | Plate size (mm) | Cake thickness (mm) | Filter chamber volume(L) | Number of filter plate (PCS) | Pressure (Mpa) | Weight (kg) | Dimension (L*W*H)(mm) |

| XZ/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XZ/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XZ/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XZ/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 | ||||

| XZ/2000-30U | 500 | 2000*2000 | 40 | 7450 | 68 | 0.5-1.5 | 36500 | 10140*3030*2400 |

| 600 | 8960 | 82 | 40000 | 11275*3030*2400 | ||||

| 800 | 11990 | 110 | 48000 | 13540*3030*2400 | ||||

| 1000 | 14900 | 127 | 56000 | 14920*3030*2400 |

FAQ

1, Do you have manual with the machine?

Yes, of course. It is in English version.

2, Can you offer us the necessary paper to do the customs clearance?

Yes, of course. We will send you the commercial invoice, sales contract, packing list, bill of lading(FOB or CFR, CIF terms), insurance policy (if CIF terms), also CO if you need.

3. Can you help us to make our products?

Yes sure we can! OEM is warmly welcomed.

4. What is warrant period for the Machine?

Usually the guarantee period is 1 year, and we will keep contact with our

customers for after-sales service. We're aim to produce better machines and let our customers be satisfied.

5. How can i get quotation?

Just send email with requirement of product and you'll get prompt response from us.

6. If we have problems when using the Machine, what should we do?

If you have any problem, just contact us, we will help you to solve it, and if necessary, we will arrange our engineers to help you in your country.

7. What about the shipping methods?

For urgent order and light weight, you can choose express: FedEx, TNT, DHL or EMS; for heavy weight, you can choose by air or by sea to save cost.