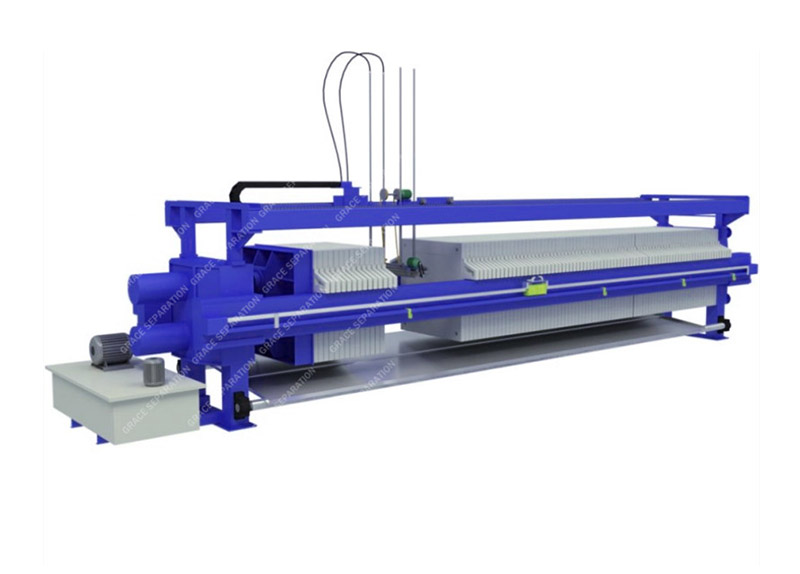

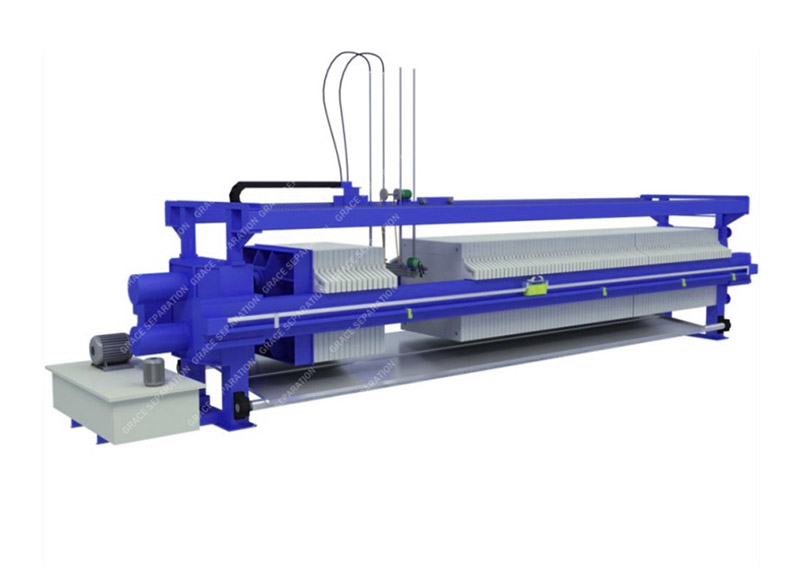

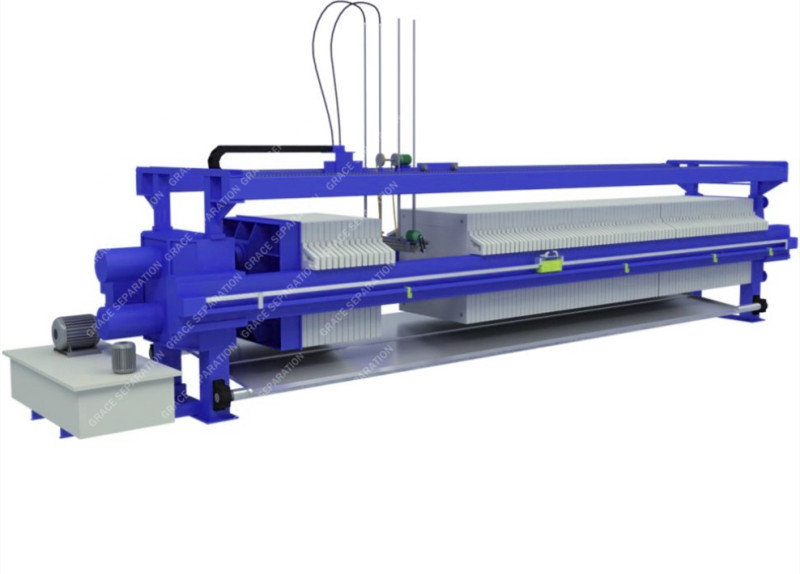

An industrial solid-liquid separation filter press is a tool used in separation processes, specifically to separate solids and liquids using the principle of pressure drive, provided by a slurry pump.

Simple Introduction:

■ Application scope: solid-liquid separation for all industry.

■ Usage : solid-liquid separation.

■ Operation: manual, semi-automatic, fully automatic

■ Delivery detail : 7-10 working days.

Introduction:

An industrial solid-liquid separation filter press is a tool used in separation processes, specifically to separate solids and liquids using the principle of pressure drive, provided by a slurry pump. The filter press is used in fixed-volume and batch operations, which means that the operation must be stopped to discharge the filter cake before the next batch can be started. The major components of a filter press are the skeleton and the filter pack. The skeleton holds the filter pack together while pressure is being developed inside the filtration chamber. The chamber however can hold a specific volume of solids.

Application industries

| Municipal wastewater treatment | Ore pulp dewatering |

| Food industry | pharmaceutical |

| Pulp and paper mill sludge | Livestock manure |

| Beverage | metallurgy |

| Leather sludge | Aquatic product sludge |