Automatic Membrane filter press specially applies to viscous material and users who require a strict cake dryness.The filter plates of membrane type filter press consists of two kinds filter plates: membrane filter plate (whose surface is flat) and chamber plate (which as depth for filter cake storage).

Introduction of automatic Membrane filter press:

The filter plates of membrane type filter press consists of two kinds filter plates: membrane filter plate (whose surface is flat) and chamber plate (which as depth for filter cake storage). The filtering process as following. Under the pressure of feeding pump, material is pumped into filter chamber, solid and liquid are separated by filter medium (filter cloth). After filter cakes formed, the compressed air will be blown into the membrane plate and inflate it to squeeze cake, thus realize lower moisture. Membrane filter press specially applies to viscous material and users who require a strict cake dryness.Filter plates are made from reinforced PP by mould pressing. Membranes are recessed with PP plates integrally. They are firm and steady, not easy to fall off, and enjoy long.

Frame: The steel frame acts as a clamping device for the filter plates.

Filter Plates: A filter cake forms in the chambers between filter plates.

Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Available options according to:

Closing mode: manual, gear drive, hydraulic;

filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

filter plate material: PP, rubber, cast iron, stainless steel;

Filter Plate size(mm): 320, 450, 630, 800,1000, 1250, 1500,2000

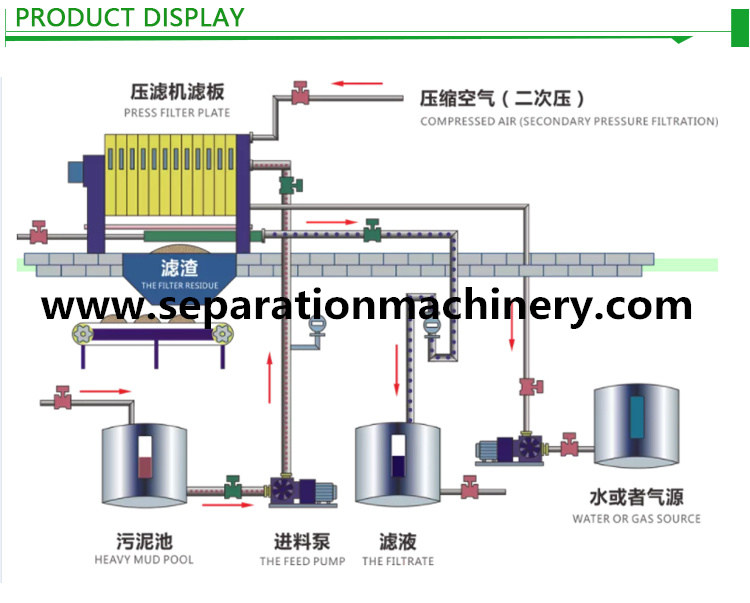

Working Principle:

Under the pressure of feeding pump, material is pumped into filter chamber, solid and liquid are separated by filter medium (filter cloth). After filter cakes formed, the compressed air will be blown into the membrane plate and inflate it to squeeze cake, thus realize lower moisture.

Applications:

· Stone fabrications

· Metal Finishing

· Mining & Energy

· Power

· Industrial Wastewater

· Municipal Wastewater

· Lime Softening

· Chemical Processing

· Ready Mixed Concrete

· Car & Truck Washes

Automatic Filter Press Technical Data:

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XZ/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XZ/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XZ/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XZ/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 | ||||

| XZ/2000-30U | 500 | 2000*2000 | 40 | 7450 | 68 | 0.5-1.5 | 36500 | 10140*3030*2400 |

| 600 | 8960 | 82 | 40000 | 11275*3030*2400 | ||||

| 800 | 11990 | 110 | 48000 | 13540*3030*2400 | ||||

| 1000 | 14900 | 127 | 56000 | 14920*3030*2400 |