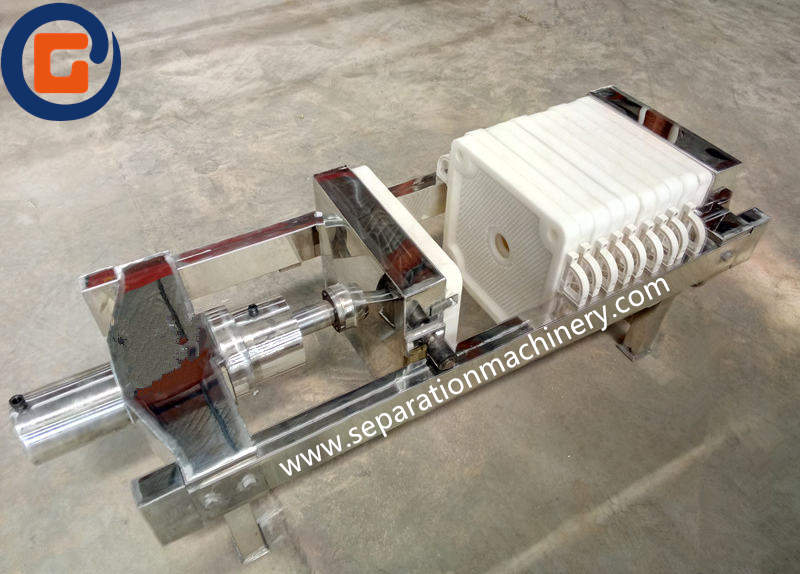

Mini small scale SS Filter Press is an ideal equipment for solid-liquid separation with small capacity,it is widely applied to many industries,such as municipal wastewater treatment, metallurgy, leather sludge etc, it can also work with conveyor and feeding pump,high efficiency,saving time and labor cost.

Introduction:

Mini small scale SS Filter Press is an ideal equipment for solid-liquid separation with small capacity,it is widely applied to many industries,such as municipal wastewater treatment, metallurgy, leather sludge etc, it can also work with conveyor and feeding pump,high efficiency,saving time and labor cost.

Working principle:

Each filter press operation includes the following steps:

1, Start the filter press:

Start the machine, pull filter plate to form filter chamber.

2, Filling the filter chamber:

During this short phase chamber are filled with sludge for filtration. Filling time depends on the flow of the feed pump.

3, Filtration:

Once the chamber have been filled continuous arrival of sludge to be dewatered provokes a rise in pressure due to the formation of an increasingly thick layer of filter sludge on the cloths. This filtration phase can be stopped manually, by a timer or more conveniently by a filtrate flow indicator which issues a stop alarm when the end of filtration rate has been reached.

4, Open filter plate, discharge filter cake:

The moving head is drawn back to disengage the first filtration chamber, the cake falls has a result of his own weight.

Application:

1, Chemical industry:

Coating, paint, silica, caustic soda, soda ash, alkali, salt mud (aluminum, aluminum polymerization acetylacetonate, gypsum, insurance, phosphor) etc.

2, Food industry:

Vegetable oil, starch sugar, plant sweet, maltose, starch, maize, seaweed, kara glue, oral liquid, beer yeast, rice wine, white wine, fruit juice, beverage, plant protein etc.

3, Pharmacy industry:

Phytic acid, calcium, Chinese traditional medicine, saccharification, growth hormone, organophosphate etc.

4, Other solid liquid separation industries.

Technical Parameters:

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XY/520-25U | 4 | 520*520 | 25 | 40 | 9 | 0.5-1.5 | 560 | 1915*700*860 |

| 6 | 60 | 14 | 630 | 2145*700*860 | ||||

| 8 | 80 | 19 | 700 | 2375*700*860 | ||||

| 12 | 120 | 29 | 830 | 2835*700*860 | ||||

| 16 | 160 | 39 | 980 | 3295*700*860 | ||||

| 18 | 176 | 44 | 1160 | 3525*700*860 | ||||

| 20 | 200 | 49 | 1360 | 3755*700*860 | ||||

| XY/700-25U | 20 | 700*700 | 25 | 250 | 24 | 0.5-1.5 | 2210 | 3120*1100*1100 |

| 30 | 380 | 37 | 2660 | 3785*1100*1100 | ||||

| 40 | 500 | 49 | 3080 | 4395*1100*1100 | ||||

| XY/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XY/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XY/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XY/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 |