Plate Frame filter press is one kind effective filtration equipment for solid-liquids separation. compared with other solid-liquid separation equipment, the filter cake has higher solidity rate and good separation effect. Filter press structure is simple, it has the characteristics of large filtering capacity.

Introduction of Plate Frame Filter Press:

Plate Frame filter press is one kind effective filtration equipment for solid-liquids separation. compared with other solid-liquid separation equipment, the filter cake has higher solidity rate and good separation effect. Filter press structure is simple, it has the characteristics of large filtering capacity and have the filtering area from small to big (filtering area from 1 m2 to 1000 m2), high operating pressure, low filter cake moisture,applicable to a variety of materials, suitable for intermittent operation.

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

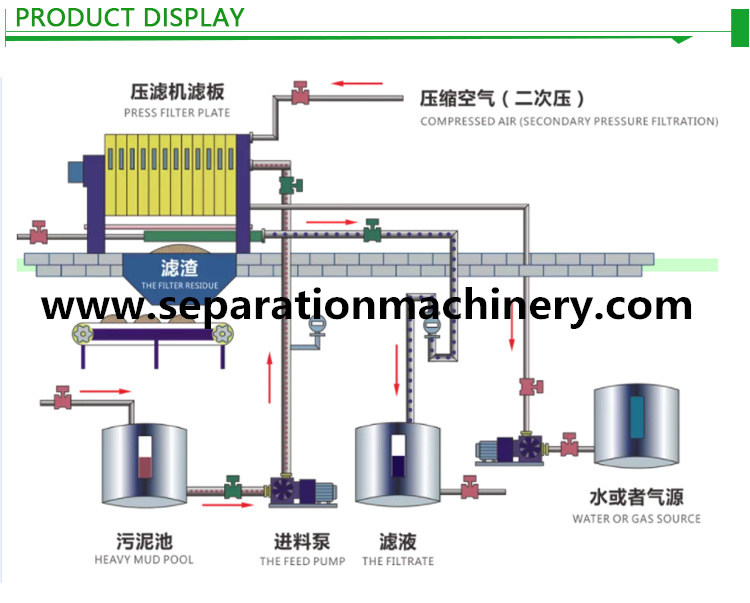

Working principle:

The mixture slurry is pumped through the mediating medium(filter cloth) ,the solid will stay in the filter chamber formed by two filter plates and gradually pile up on the filter cloth to form a filter cake. and the liquid part is permeable to filter cloth, then the clear liquid that contains no solid flow out of the filter press.The filtration chamber of the chamber filter press is composed of two adjacent filter plate. The mainly advantage of this type is less wear during feeding, fast filtration, high temperature and high pressure resistance, good seal performance, uniform filter cake washing , moisture content is low, and the filter chamber pressure are evenly not easy to damage filter plate, It is suitable for all solid-liquid separation industries.

Application scope of Plate Frame Filter Press Machine:

Filter Press Machine are widely applied in various kinds of solid-liquid procession, such as petroleum, chemical, metallurgy, environmental protection, food, beverage, pharmaceutical, sugar, starch, paper, coal washing, ceramics, mineral processing, and many other industries.

Automatic Filter Press Technical Data:

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XZ/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XZ/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XZ/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XZ/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 | ||||

| XZ/2000-30U | 500 | 2000*2000 | 40 | 7450 | 68 | 0.5-1.5 | 36500 | 10140*3030*2400 |

| 600 | 8960 | 82 | 40000 | 11275*3030*2400 | ||||

| 800 | 11990 | 110 | 48000 | 13540*3030*2400 | ||||

| 1000 | 14900 | 127 | 56000 | 14920*3030*2400 |

Hydraulic Filter Press Technical Data:

| Model | Filter area(m2) | Plate size(mm) | Cake thickness(mm) | Filter chamber volume(L) | Number of filter plate(PCS) | Pressure(Mpa) | Weight (kg) | Dimension(L*W*H)(mm) |

| XY/520-25U | 4 | 520*520 | 25 | 40 | 9 | 0.5-1.5 | 560 | 1915*700*860 |

| 6 | 60 | 14 | 630 | 2145*700*860 | ||||

| 8 | 80 | 19 | 700 | 2375*700*860 | ||||

| 12 | 120 | 29 | 830 | 2835*700*860 | ||||

| 16 | 160 | 39 | 980 | 3295*700*860 | ||||

| 18 | 176 | 44 | 1160 | 3525*700*860 | ||||

| 20 | 200 | 49 | 1360 | 3755*700*860 | ||||

| XY/700-25U | 20 | 700*700 | 25 | 250 | 24 | 0.5-1.5 | 2210 | 3120*1100*1100 |

| 30 | 380 | 37 | 2660 | 3785*1100*1100 | ||||

| 40 | 500 | 49 | 3080 | 4395*1100*1100 | ||||

| XY/800-30U | 30 | 800*800 | 30 | 480 | 29 | 0.5-1.5 | 2080 | 3650*1200*1160 |

| 40 | 640 | 39 | 2380 | 4210*1200*1160 | ||||

| 50 | 800 | 49 | 2700 | 4770*1200*1160 | ||||

| 60 | 960 | 59 | 3060 | 5330*1200*1160 | ||||

| XY/870-30U | 50 | 870*870 | 30 | 760 | 37 | 0.5-1.5 | 3580 | 4220*1300*1250 |

| 60 | 920 | 45 | 3980 | 4710*1300*1250 | ||||

| 70 | 1080 | 53 | 4500 | 5200*1300*1250 | ||||

| 80 | 1200 | 59 | 5200 | 5560*1300*1250 | ||||

| XY/1000-30U | 80 | 1000*1000 | 30 | 1303 | 46 | 0.5-1.5 | 3470 | 5160*1500*1350 |

| 90 | 1468 | 52 | 4040 | 5525*1500*1350 | ||||

| 100 | 1635 | 58 | 4360 | 5890*1500*1350 | ||||

| 120 | 1966 | 70 | 4960 | 6620*1500*1350 | ||||

| XY/1250-30U | 120 | 1250*1250 | 30 | 1800 | 44 | 0.5-1.5 | 6600 | 5410*1750*1600 |

| 140 | 2120 | 52 | 7200 | 5940*1750*1600 | ||||

| 150 | 2280 | 56 | 7500 | 6200*1750*1600 | ||||

| 160 | 2400 | 59 | 7750 | 6400*1750*1600 | ||||

| 180 | 2720 | 67 | 8500 | 7230*1750*1600 | ||||

| 200 | 3000 | 74 | 9000 | 7690*1750*1600 | ||||

| 250 | 3800 | 93 | 10500 | 9015*1750*1600 |