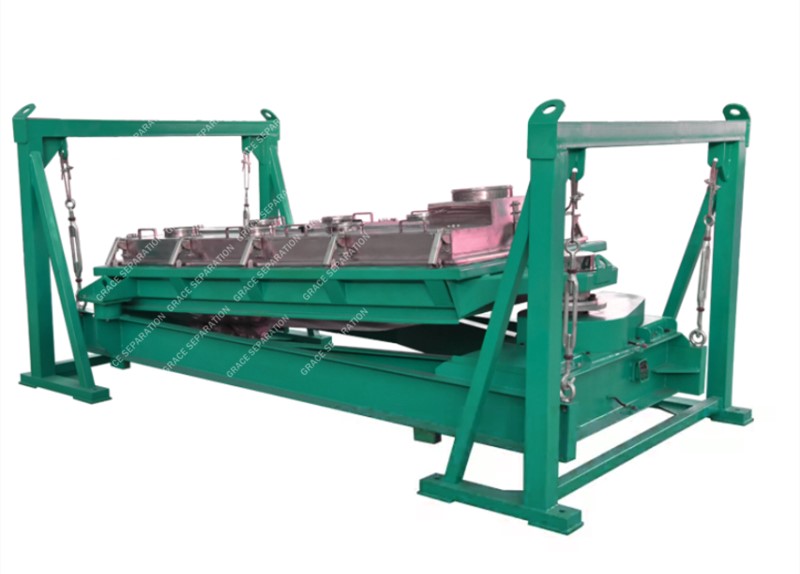

Gyratory vibrating separator is a new developed equipment particularly for granules separation. The main function is to provide accurate separation of materials without product deterioration, thereby resulting greater product yields at higher production rates.

Introduction

Gyratory vibrating separator is a new developed equipment particularly for granules separation. The main function is to provide accurate separation of materials without product deterioration, thereby resulting greater product yields at higher production rates.

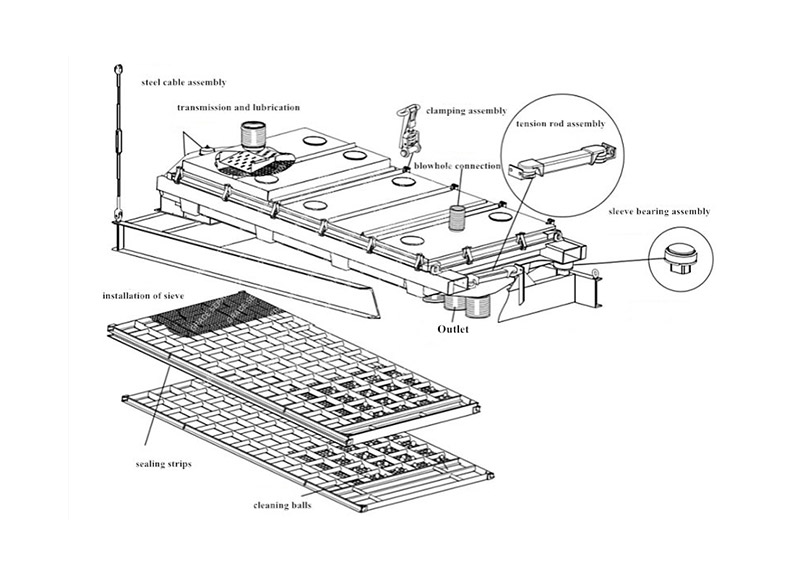

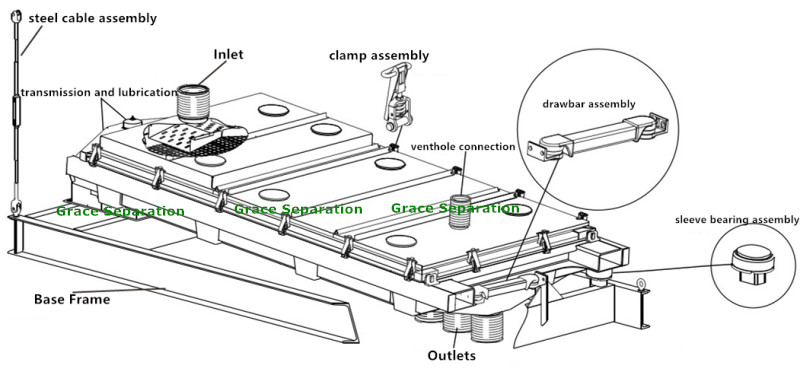

This machine consists of top cover, top screen fame, spacer, bottom screen fame, the base space and the screen box. The unique gyratory motion of the near horizontal screen surface and the available screen mesh cleaning system secure the gyratory vibrating screen quality as a high capacity product that efficiently developed for materials screening purposes.

Products Features

All components are easily accessible and removable.

No vertical vibration, longer life span of mesh.

Each layer is installed with an anti-blocking and cleaning facility.

Lower headroom permits operation in confined areas.

More product yields at same production rates.

Low energy consumption, higher screening efficiency.

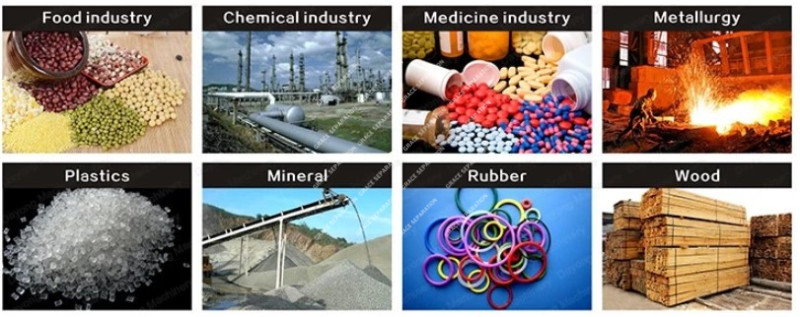

Application industries

Gyratory vibrating separator is a new sieving device which is developed mainly aiming at screening of bulky urea and fertilizer, also widely used for sieving sugar, salt, stone powder, grain, graphite etc.

Structure and technical parameters

| MODEL | GRS0815 | GRS1021 | GRS1225 | GRS1530 | GRS1836 |

| Screen size(mm) | 800×1500 | 1000×2100 | 1200×2500 | 1500×3000 | 1800×3600 |

| Dip angle of screen | 5-10° | ||||

| Screen Area | 1.2㎡ | 2.1㎡ | 3㎡ | 4.5㎡ | 6.4㎡ |

| Stroke of Screen | 63.5mm | 63.5mm | 72mm | 72mm | 81mm |

| Motor Power | 1.5KW | 2.2KW | 3.7KW | 5.5KW | 7.5KW |

| QTY. of Level | 1-3 | ||||

| Rotary Frequency | 110-180r/min | ||||