Rotary vibrating screens are widely used in the metal metallurgy industry to screen various metal powders such as aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, Refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Introduction:

Rotary vibrating screens are widely used in the metal metallurgy industry to screen various metal powders such as aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, Refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

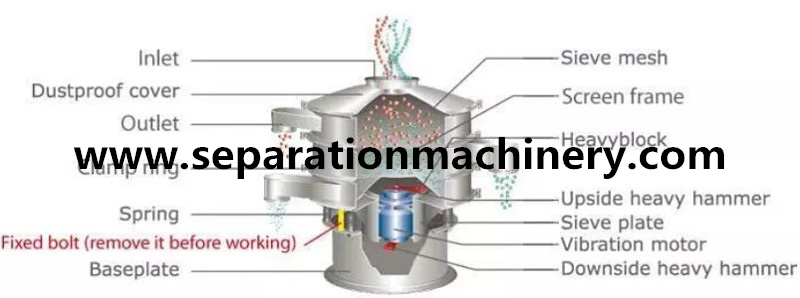

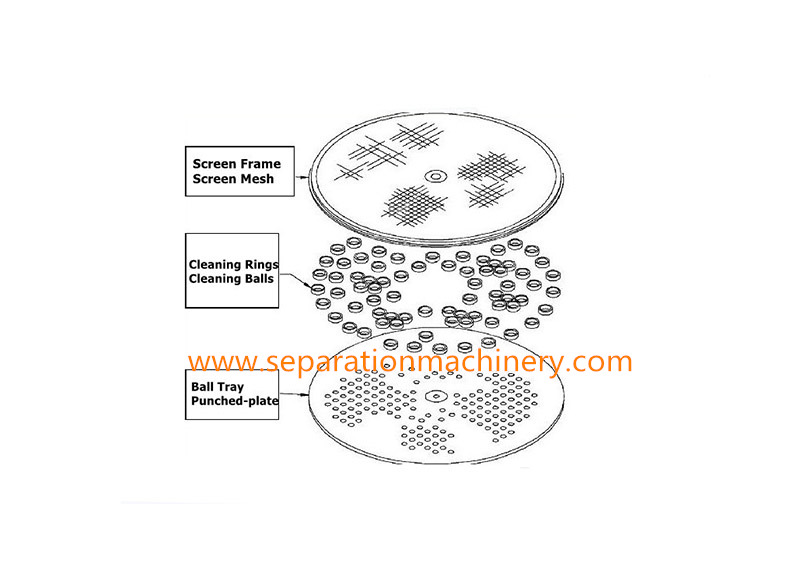

Structure and working principle:

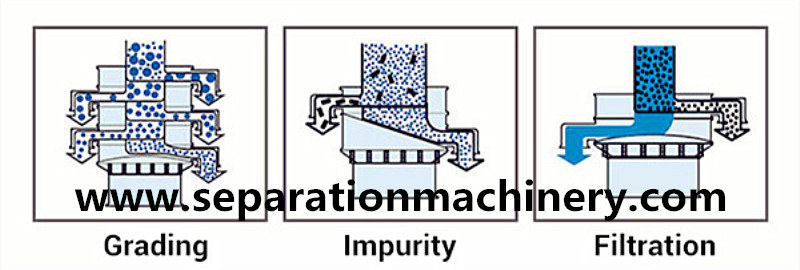

The fundamental principle of Industrial rotary vibrating screen sieve is that the eccentric hammers installed on the top and bottom ends of motor changes the rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removal of impurities.

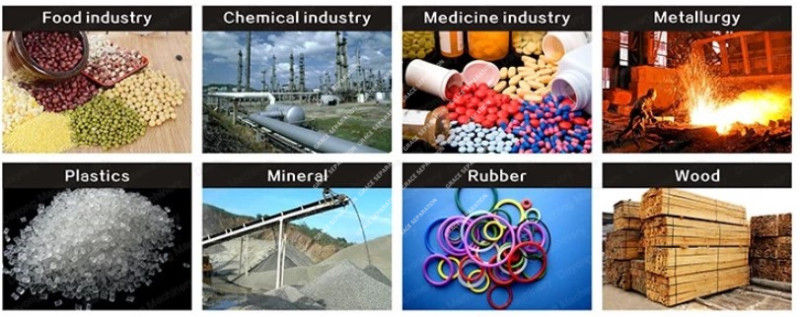

Applicable industry:

Chemical industry: resin, paint, industrial medicine, cosmetics, paint, Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Metals, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy carbon acid Calcium, quartz sand, etc.

Other industries: waste oil, wastewater, dyeing and finishing wastewater, papermaking, additives, activated carbon, etc.

Technical Parameters:

| Model | Screen Diameter (mm) | Screen Area (m2) | ScreenDecks | Power(KW) | Maximum size input |

| GX-400 | 350 | 0.10 | 1-5 | 0.18 | 20mm |

| GX-600 | 550 | 0.24 | 1-5 | 0.25 | 20mm |

| GX-800 | 760 | 0.44 | 1-5 | 0.5 | 30mm |

| GX-1000 | 950 | 0.71 | 1-5 | 0.75 | 30mm |

| GX-1200 | 1150 | 1.03 | 1-5 | 2.2 | 30mm |

| GX-1500 | 1430 | 1.65 | 1-5 | 2.2 | 50mm |

| GX-1800 | 1730 | 2.35 | 1-3 | 2.5 | 50mm |

| GX-2000 | 1910 | 2.98 | 1-3 | 2.5 | 60mm |

Q: What information do I need to provide for getting an accurate quotation for Industrial rotary vibrating screen sieve?

1. Material's name, bulk density, and water content?

2. Capacity you required per hour? (kg/h)

3. What's the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer you need?

6. Voltage and frequency?