Rotary Vibrating Screen is a high-precision fine screening machine,used mainly for sieving,scalping,removing impurity,grading and filtering to improve product quality. It takes 3-5 minutes to change the screen quickly. It is fully enclosed and suitable for screening and filtering of particles, powder and mucilage.

Introduction:

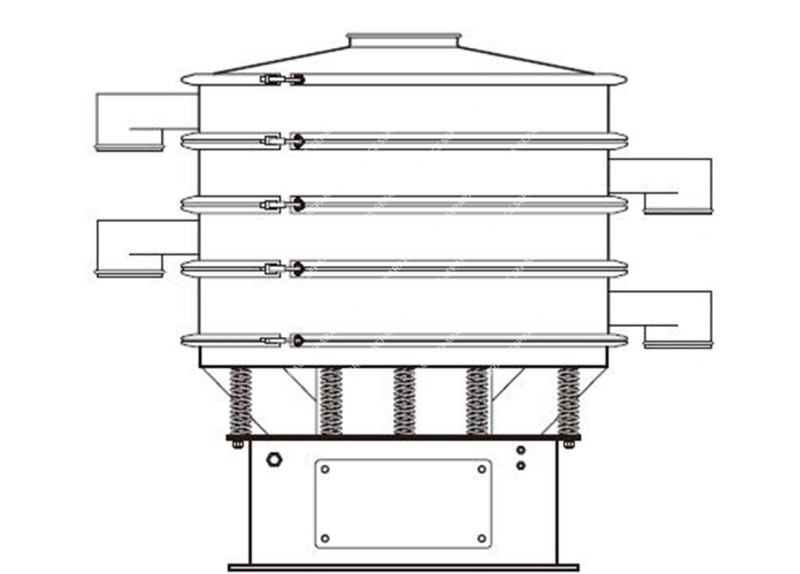

Vibratory separator is a high-precision fine screening machine,used mainly for sieving,scalping,removing impurity,grading and filtering to improve product quality. It takes 3-5 minutes to change the screen quickly. It is fully enclosed and suitable for screening and filtering of particles, powder and mucilage. Vibrating screen is made up of an upright motor as an excitation source. The upper and lower ends of the motor are equipped with an eccentric weight to convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transmit this motion to the screen surface. Adjusting the phase angle of the upper and lower ends can change the trajectory of the material on the screen surface.

Working principle:

The fundamental principle of Industrial rotary vibrating screen sieve is that the eccentric hammers installed on the top and bottom ends of motor changes the rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removal of impurities.

Application industries of rotary vibrating screen:

Chemical Industry: colophony, dope, industry leechdom, cosmetic, paint

Grinding materials & china industry: alumina, quartz, slurry, kaolin, carborundum, sprayer dust.

Food Industry: sugar, rice powder, milk powder, soybean milk, angel cake, sauce, juice.

Paper Making Industry: dope, white soil slurry, black and white liquid, disposed liquid, paper-making liquid and waste water recycling.

Metallurgy& Mining Industry: aluminum powder, ceruse, copper powder, ore alloy powder, welding rod powder, dioxide manganese, electrolyze copper powder, electromagnetic material, rubbing powder, fire-proof material, kaolin, lime, heavy calcium carbonate.

Technical Parameters:

| Model | Screen Diameter (mm) | Screen Area (m2) | ScreenDecks | Power(KW) | Maximum size input |

| GX-400 | 350 | 0.10 | 1-5 | 0.18 | 20mm |

| GX-600 | 550 | 0.24 | 1-5 | 0.25 | 20mm |

| GX-800 | 760 | 0.44 | 1-5 | 0.5 | 30mm |

| GX-1000 | 950 | 0.71 | 1-5 | 0.75 | 30mm |

| GX-1200 | 1150 | 1.03 | 1-5 | 2.2 | 30mm |

| GX-1500 | 1430 | 1.65 | 1-5 | 2.2 | 50mm |

| GX-1800 | 1730 | 2.35 | 1-3 | 2.5 | 50mm |

| GX-2000 | 1910 | 2.98 | 1-3 | 2.5 | 60mm |

Material:

Q: What information do I need to provide for getting an accurate quotation for Industrial rotary vibrating screen sieve?

1. Material's name, bulk density, and water content?

2. Capacity you required per hour? (kg/h)

3. What's the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer you need?

6. Voltage and frequency?