The glass-lined reactor is a corrosion-resistant chemical equipment that lining glass-lined porcelain glaze containing high silica on the inner surface of a steel container, and then firmly and uniformly adheres to the metal surface after high-temperature burning.

Overview

Glass-lined reactors are chemical equipment that line high-silica-containing glass-lined porcelain enamel on the inner surface of a steel container, and then burn at high temperature to be firm and evenly adhere to the metal surface. Therefore, the enamel reactor has the double advantages of glass stability and metal strength, and is an excellent corrosion-resistant chemical equipment. The difference between the open type and the closed type is that the open kettle lid can be opened, and the closed type cannot be opened. The open type is connected by a clamp, which is more convenient to disassemble and assemble. The advantages of the closed type are better sealing performance. many. Products such as enamel reactors and chemical containers have been widely used in reactions, evaporation, concentration, synthesis, extraction, polymerization, saponification in industrial production and scientific research in chemical, pharmaceutical, dye, pesticide, organic synthesis, petroleum, food manufacturing and national defense industries. , Mineralization, chlorination, nitration, etc. to replace expensive stainless steel and non-ferrous metals. The chemical reaction tanks and enamel / glass-lined reactors produced by our company are all fired with electric furnaces with specific specifications. Wear-resistant, heat-resistant, easy to scrub, non-polluting materials, low price, not easy to jump porcelain.

Features of glass lined reactor

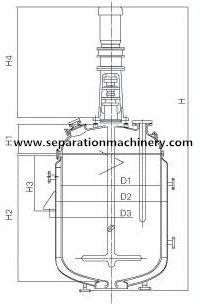

The glass-lined reactor is composed of a kettle body, a kettle lid, an agitator, a jacket, a support and transmission device, a shaft seal device, etc. The material and opening can be formulated according to the user's process requirements.

According to the heating form, it can be divided into: electric heating glass lined reaction kettle, thermal oil heating glass lined reaction kettle, steam heating glass lined reaction kettle, water heating glass lined reaction kettle, open flame heating reaction kettle, etc.

According to the jacket form, it is divided into: jacketed glass-lined reactor and outer plate half-tube glass-lined reactor. The jacketed heat-conducting oil heating type is equipped with a flow guide device.

The glass-lined reactor agitator generally has paddle type, anchor type, frame type, ribbon type, scraped wall type, axial flow type and so on. The high-speed reaction kettles are divided into impeller type, turbine type, high shear type and propeller type for customers to choose according to the process.

The reaction forms of the reactor agitator include ordinary motors, explosion-proof motors, electromagnetic speed-regulating motors, inverters, etc. The reducers include cycloid pinwheel, worm gear, and planetary stepless speed change.

Shaft seals are divided into ordinary water-cooled packing seals, combined PTFE packing seals, mechanical seals, and double-end mechanical seals.

The output form of the reaction kettle is a ball valve, a down valve, and a tetrafluoro ball valve.

The supporting accessories for glass-lined reactors include: serpentine cooling coils, high-level tanks, distillation columns, vertical condensers, elbows, etc. for customers to choose.

Working pressure: 0.3Mpa inside the tank 0.6Mpa inside the jacket

Design pressure: 0.4Mpa in tank pressure 0.6Mpa in jacket

Working temperature: 20 ~ 200 ℃ in the jacket, jacket 20 ~ 200 ℃

Design temperature: 200 ℃ in the tank 200 ℃ in the jacket

Container category: Class I (Class I)

Media characteristics: non-toxic, non-explosive

Main material: Q245R Q245R

Application

Glass-lined reactors have been widely used in reactions, evaporation, concentration, synthesis, extraction, polymerization, saponification, mineralization in industrial production and scientific research in chemical, pharmaceutical, dye, pesticide, organic synthesis, petroleum, food manufacturing and national defense industries. , Chlorination, nitration, etc. to replace expensive stainless steel and non-ferrous metals.

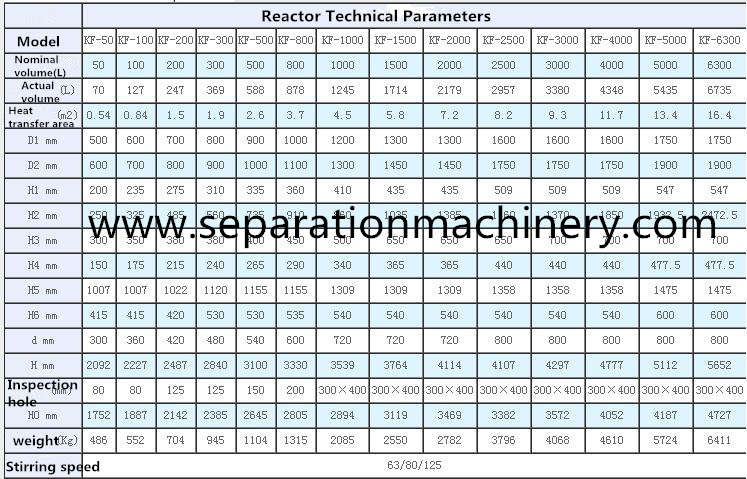

Technical Parameter