The Pharmaceutical Chemical Stainless Steel Stirred Tank Reactor Vessel are applicable to the reaction in chemical industry and pharmacy. The reactor body can be provided with the structure honeycomb jacket, pipe jacket or overall jacket, and also can be heated and cooled. The sealing device is mechanical sealing.

Overview

The Pharmaceutical Chemical Stainless Steel Stirred Tank Reactor Vessel are applicable to the reaction in chemical industry and pharmacy. The reactor body can be provided with the structure honeycomb jacket, pipe jacket or overall jacket, and also can be heated and cooled. The sealing device is mechanical sealing. Heating or cooling can be of insert-set, semicanal or sepentine structure. Heaitng methods can be steam heating, electric heating and heat-conduction oil, to meet the demand of many different working surroundings as acidity, high temperature, abrason, corrision and so on. Acid resistance, high temperature resistant, scuff resistence, anticorrosion.

Structural features

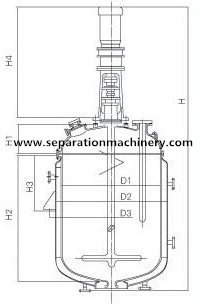

1.The reaction kettle is composed of kettle body, kettle cover, agitator, heating jacket, supporting and driving devices, seal devices, and etc. and equipped with electric heating rods.

2.Considering clients’ different producing technology and operating conditions, usually mixing patterns are divided into anchor, propeller, turbo, push or frame. The support seat has two kinds, hanging or back supporting type. There are holes for oil in and out, venting, and temperature monitoring in the jacket. At the bottom of the kettle, there is a discharge hole.

Material: SUS304 or S.S.316L

Mixing type: anchor type, frame type or paddle type

Mixing structure: cycloid pin wheel reducer or stepless reducer

Sealing equipment: Mechanical sealing

Heating or Cooling: jacket, half pipe or coil pipe

Heating way: steam heating, electrical heating or heat conduct oil.

Volume: can be made as per customer requirements

Measure: can be made as per customer requirementsMaterial: SUS304 or S.S.316L

Mixing type: anchor type, frame type or paddle type

Mixing structure: cycloid pin wheel reducer or stepless reducer

Sealing equipment: Mechanical sealing

Heating or Cooling: jacket, half pipe or coil pipe

Heating way: steam heating, electrical heating or heat conduct oil.

Volume: can be made as per customer requirements

Measure: can be made as per customer requirements

Application

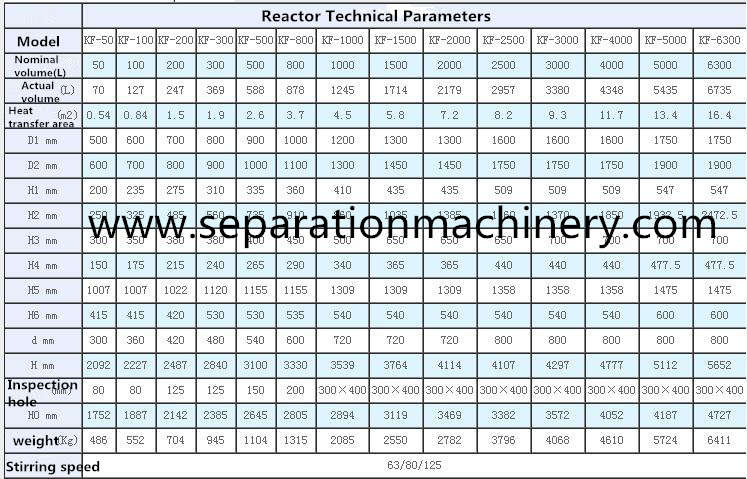

Technical Parameter