Tubular Bowl Centrifuge Separators used for separating various emulsion, especially for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter, such as transformer oil, turbine oil, lubricant, fuel oil, dye, fat,etc. and treating sewage and separating oil and water.

Brief Description

Tubular Bowl Centrifuge Separators used for separating various emulsion, especially for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter, such as transformer oil, turbine oil, lubricant, fuel oil, dye, fat, sapnificatio and various micropowder and for purifying span-80 liquid separating various oral liquid and medical liquid and "920" and plasma and biologic medicine, extracting plasma from animals' blood, refining phosphatide of bean, etc. and treating sewage and separating oil and water.

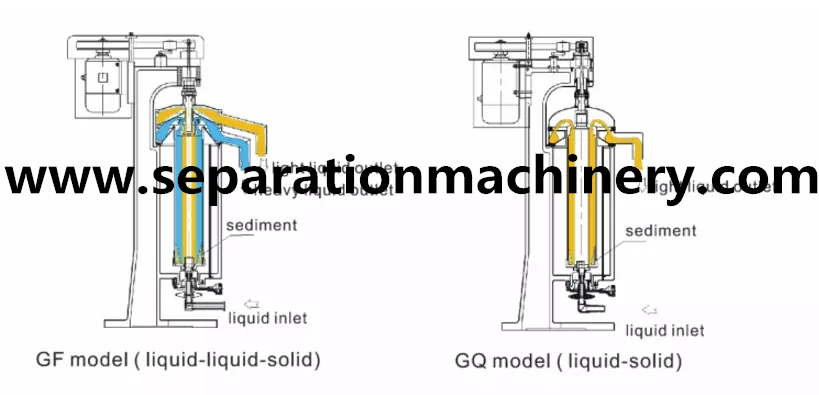

Working principles

The machine is composed of main body, transmission device, drum, liquid collecting tray, and liquid-feeding bearing base. There is a flexible main axis on the top of drum, and a damping floating bearing at its bottom. With the linked buffering device, the main axis is connected with the passive wheel. Through the conveyor and the fastening wheel, motor provides power for the passive wheel, so the drum rotates around itself axis by high speed, and form strong centrifuge force field. Materials are launched from the bottom feeding inlet, by the centrifugal force, liquid flows upward along the drum wall, and is separated to layers because their different density.

Application

It is used for separating various emulsion, especially adaptable for liquid-liquid separation with slight gravity difference and liquid-liquid-solid separation with a little foreign matter, such as separation of various oil and micropowder, extract liquid from plants, separation of plasma and cell,separation of milk cream.

(1) Oil separation(Avocado oil,Biodiesel, Coconut oil ,vegetable oil degumming ,de-soap, dewater, oil and water separation etc)

(2) Clarifying process for liquid solid product (oral liquid)

(3) Extraction of protein, seaweed and jelly(plant extraction, herb extraction,pigment extraction)

(4) Refined molasses

(5) Separation of blood

(6) Settlement of bacteria (yeast, E.coli, lactobacillus, bacillus subtilis, nitrobacter etc)

(7) Purifying paint, dye, various resin

(8) Processing of granular, crystalline and fibrous suspensions

(9) Separation of filterable and non-filterable sludge.

Technical parameter

| Model | Unit | GQ/GF45 | GQ/GF75 | GQ/GF105 | GQ/GF115 | GQ/GF125 | GQ/GF150 |

| Bowl Diameter | mm | 45 | 75 | 105 | 115 | 125 | 150 |

| Bowl Speed | r/min | 10000-30000 | 19000 | 16300 | 16300 | 15000 | 13400 |

| Separation factor | -- | 19800 | 15200 | 15620 | 17000 | 15700 | 14300 |

| Bowl Volume | L | 0.45 | 2.2 | 6 | 7 | 8 | 10 |

| Throughput Capacity | L/H | 100 | 600 | 1200 | 1300 | 1500 | 2500 |

| Motor | kw | 0.55 | 1.5 | 2.2 | 3.0 | 3.0 | 3.0 |

| Weight | kg | 90 | 260 | 500 | 520 | 530 | 600 |

| Dimension(L*W*H) | mm | 500*420*760 | 760*450*1120 | 550*850*1600 | 600*900*1600 | 650*950*1600 | 700*1000*1600 |

Our centrifuge separators catalogue