Tubular centrifuge is the separator with the highest centrifugal separation factor among various centrifuges currently used in industrial production. It has the advantages of compact structure, small size, large separation factor, and few auxiliary equipment.

Introduction

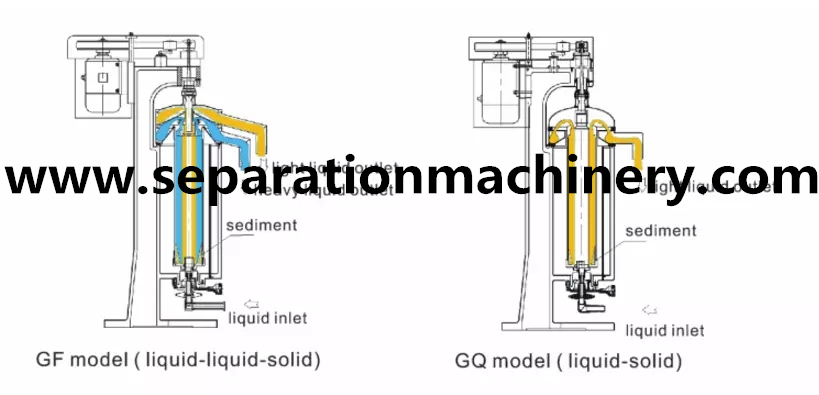

Tubular centrifuge is the separator with the highest centrifugal separation factor among various centrifuges currently used in industrial production. It has the advantages of compact structure, small size, large separation factor, and few auxiliary equipment. It is mainly suitable for the solid content of materials less than 2%, the solid phase particles can be as small as 2-5 microns, and the clarification of the suspension with a small difference in the density of the solid and liquid phases. It is also suitable for the separation of emulsions with a small difference between light and heavy liquid phases and high dispersibility.

Working principle

Application

It is widely used in chemical, light industry, pharmaceutical, food and other industries. Typical separated materials are: food, medicinal liquid, fruit juice, herbal tea beverage, coconut milk and soy milk, health wine, yeast liquid, bacteria, algae harvesting, etc.

Technical Parameters

| Model | Unit | GQ/GF45 | GQ/GF75 | GQ/GF105 | GQ/GF115 | GQ/GF125 | GQ/GF150 |

| Bowl Diameter | mm | 45 | 75 | 105 | 115 | 125 | 150 |

| Bowl Speed | r/min | 10000-30000 | 19000 | 16300 | 16300 | 15000 | 13400 |

| Separation factor | -- | 19800 | 15200 | 15620 | 17000 | 15700 | 14300 |

| Bowl Volume | L | 0.45 | 2.2 | 6 | 7 | 8 | 10 |

| Throughput Capacity | L/H | 100 | 600 | 1200 | 1300 | 1500 | 2500 |

| Motor | kw | 0.55 | 1.5 | 2.2 | 3.0 | 3.0 | 3.0 |

| Weight | kg | 90 | 260 | 500 | 520 | 530 | 600 |

| Dimension(L*W*H) | mm | 500*420*760 | 760*450*1120 | 550*850*1600 | 600*900*1600 | 650*950*1600 | 700*1000*1600 |